How to cut back on costs with an efficient spoon

In order to remain competitive and profitable, you need to know your cost structure precisely. If you find a way to reduce costs, you will not only be more competitive, but you can get more work, win more projects and generate more profit.

Many people think that every excavator spoon is the same: they dig holes where something is built later.

If you are a constructor, undertaking smaller or larger projects, the success of your work depends not only on winning the project, but also on pricing competitively. This is often the most complex part of the job, as a good example for value for money, the customer expects real value and the work must be completed within the budget by the deadline.

If you work 30% more efficiently, that’s exactly what happens. Every 4th day is free: no fuel, no cost, no depreciation. Your competitors will certainly not be able to keep up with you if every 4th day of yours is free.

Save with a more efficient bucket

During our design and testing process, we found that if we optimize the spoon and use the teeth that best fit the task, we reduce the penetration resistance, so we can achieve up to 30% increase in efficiency.

This change has a significant impact on the costs of larger projects, where the costs of digging, including channels, clean water, electricity and infrastructure, are huge.

If the machine works 30% more efficiently, it uses 30% less fuel first. The cost of the job is also reduced as much less time is needed to complete the job. There is also a 30% reduction in operating time, which can delay the required maintenance. Emissions are also reduced by 30% as less fuel is needed.

If the teeth (orange part in the picture) wear out and the digging will be continued with the adapter, the teeth will simply fall off. Special attention should be paid to avoid wearing the teeth completely. The tooth itself can even be replaced by the operator, but the adapter needs professional workshop work, which can lead to a potential loss of production.

The Combi Parts teeth sold by our company are very easy to replace.

How much can be saved with a more efficient spoon?

On a 5-ton machine, you can save about 5 million HUF a year, on larger machines, of course, proportionally more.

The tests for this were done by the Australian Engineering.

Guaranteed efficiency

The test was done with the same machine but with two different types of spoons. Both spoons worked one to one hour to make the result comparable. The machine and the operator did not change, only the spoon was replaced. 10 tests were performed on machines of different sizes between 1 and 22.5 tons. The results are very similar, in some cases even better than the 30% efficiency increase!

In addition to the operator and fuel, the spoon primarily determines the efficiency of the excavator.

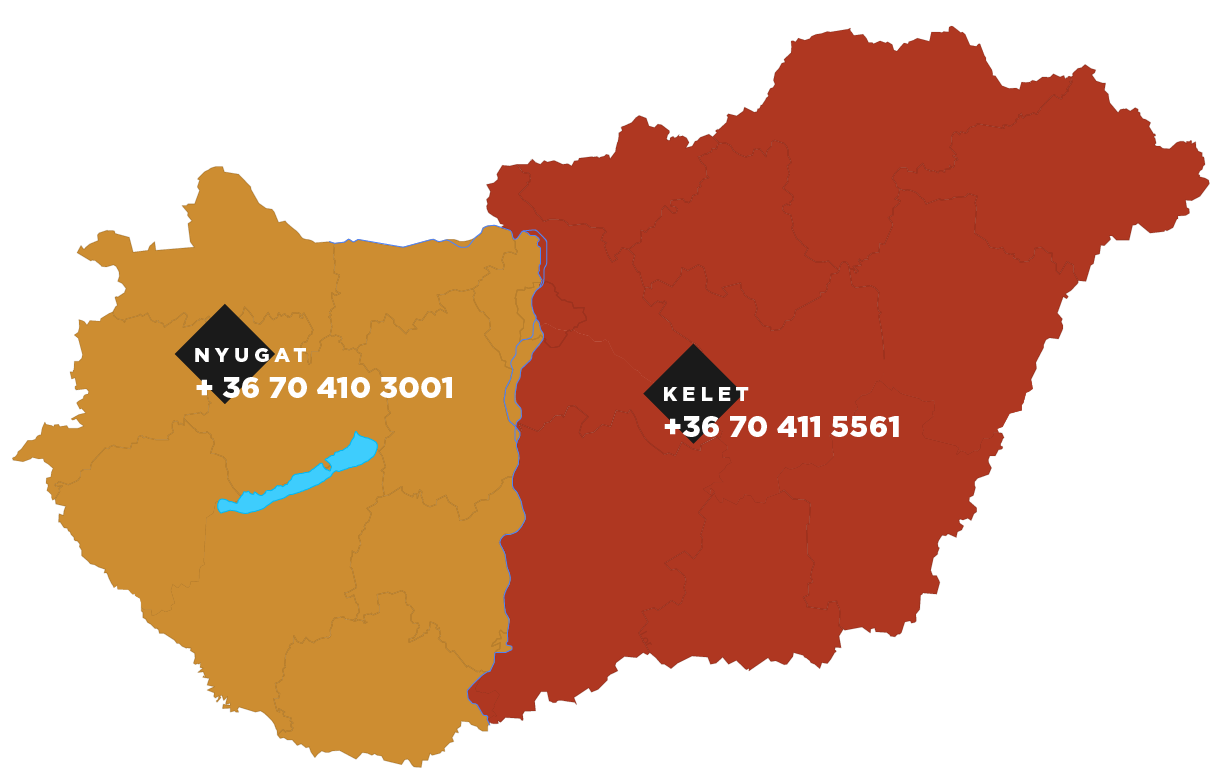

In conclusion, if you want to get contracted for large-scale projects and your buckets are not working efficiently, you won’t be able to compete with companies that use more efficient spoons. If you have any questions regarding our fittings, do not hesitate to contact us.